Kitamura PTFE Micropowder is an ideal additive for plastic compounding for wear and friction improvement.

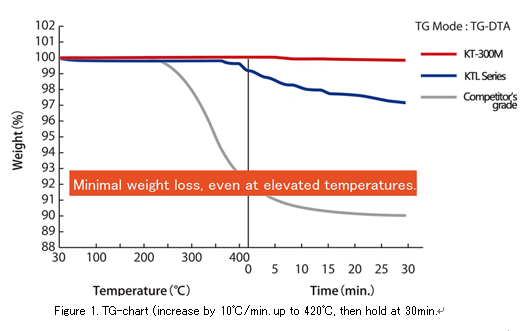

It is sintered PTFE and has a higher molecular weight than unsintered PTFE. Therefore, its dimensional stability is excellent, heat resistance is very high (over 400℃), and wear resistance is outstanding.

It is widely used as a special additive for tribological purposes, especially for high performance polymers such as PEEK, PPA and PPS. It is also frequently used for plastics such as POM, which cannot tolerate the thermal decomposition of HF gas from PTFE.

Heat resistance

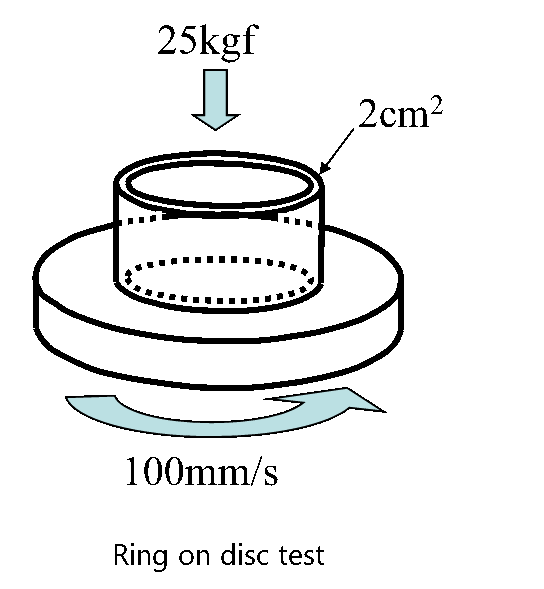

Table 1. Weight loss of Phenol resin with PTFE by Ring on disc test

Sample | Amount of addition | Wear Resistance |

(Weight loss/hour) | ||

BLANK | 0% | 180 mg |

KT-300M | 3% | 15 mg |

KTL series | 3% | 69 mg |

Other PTFE 1 | 3% | 101 mg |

Other PTFE 2 | 3% | 185 mg |

General properties

KT-300M | KTL series | |

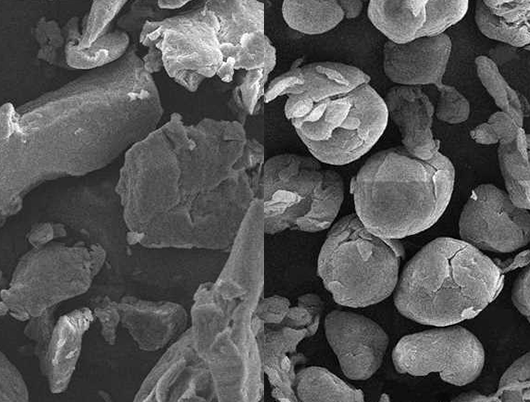

MAX. particle size | 148.00μm | 88.00μm / 62.00μm |

D50 (median diameter) | 40.00μm | 20.00μm / 10.00μm |

Melting point (DSC) | 325~335℃ | 325~335℃ |

MAX. processing temperature | 450℃ | 370~430℃ |

Volatile loss (150℃/2h) | 0.05wt.% or less | 0.10wt.% or less |

Apparent density | 0.65g/ml | 0.45~0.60g/ml |

Specific gravity | 2.1~2.2 | 2.1~2.2 |

Appearance | White powder | White powder |

Whiteness level | 95.00 or more | 95.00 or more |

FDA (CFR177.1550) | Conformed | Differ by grade |

FDA (CFR175.300) | Conformed | Conformed |